Jul 062018

ICH Q12: Guideline on Technical and Regulatory Considerations for Pharmaceutical Product Lifecycle Management, 1-2

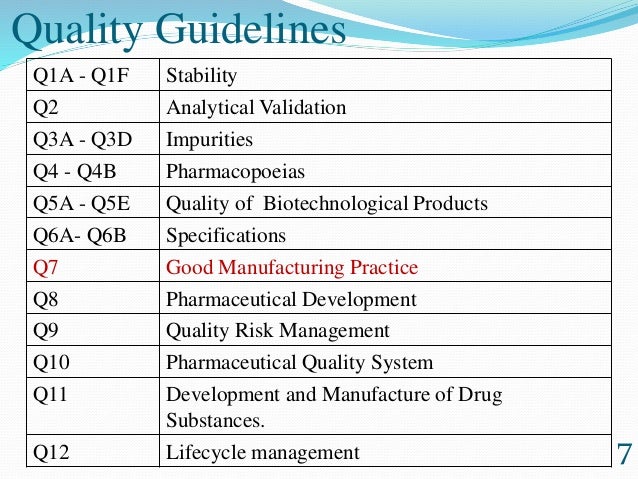

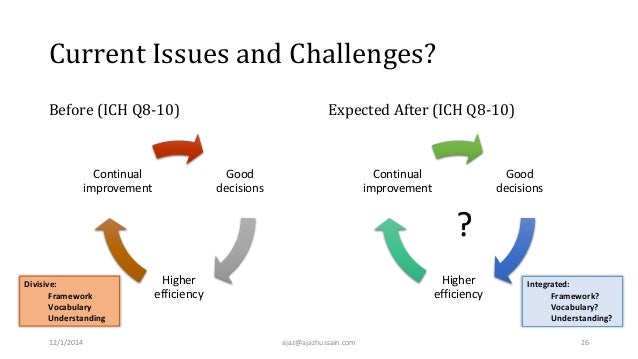

Recent ICH quality guidelines (Q8–Q11)(3−6) have focused on providing guidance on the development and manufacture of drug substances (Q11)(6) and drug products (Q8),(3) showing “baseline” and “enhanced” scientific approaches, and utilizing quality risk management tools (Q9) within the pharmaceutical quality management system (Q10). To further support the implementation of these development and manufacturing approaches, ICH recognized the value in providing tools and approaches for the management of post-approval chemistry, manufacturing, and controls (CMC) changes based on product and process understanding that could be employed by all ICH participants. Several useful tools had been established in different regions, and it was recognized that pharmaceutical innovation and continuous improvement would be optimally supported if best practices could be employed in similar ways across the regions. Achieving this harmonization would result in more efficient manufacture and change and would also increase the value of the pharmaceutical quality system and support continued optimization of the utilization of valuable resources within regulatory agencies and inspectorates (e.g., toward oversight of critical rather than noncritical changes, incentivizing industry’s understanding and management of manufacturing). The ICH Concept Paper for the development of this guidance was endorsed in 2014.(7)

The drafted consensus document is now available for public comment (step 2 of the ICH process),(8) with comments being collected by the regions during 2018 (with various comment deadlines).

The draft guidance includes some potentially very important approaches for future CMC change management, and importantly, the tools and approaches being developed are seen as usable across the range of pharmaceutical product types (including drug–device combinations) and applicable to existing products as well as newly approved products.

An approach of particular importance that is included in the guideline is the “post-approval change management protocol” (PACMP), which allows for specific changes to be predescribed to regulators and agreement to be reached on the scientific approach and data expectations that will support the change. This ability to predefine how to successfully make a change will bring great clarity and predictability to the planning and prosecution of, particularly, complex change types (often viewed as major changes needing “prior approval” in current regulatory change systems). Furthermore, the predetermination of data necessary to support the change allows for the final communication of the change to be a simple matter of confirming the suitability of the change with the expected data and for the regulatory change class to be reduced on the basis of the prior agreement of the change management approach. Importantly, a PACMP can be either agreed for a single change for a single product or constructed and agreed in a more wide-ranging manner to support multiple similar changes to be conducted on more than one product. This is of immense potential value to industry and regulators alike. Annex II of the draft guideline provides illustrative examples of different types of PACMPs, giving an example of a PACMP for a single change (to a manufacturing site for a drug substance) and an example of the more general management of such a site change.

In a section of the guideline on supporting post-approval changes for marketed products, where considerable manufacturing experience has been accrued, important approaches are given for the management of changes in analytical procedures and discussing how data requirements for changes (for stability data) can be impacted by product and process understanding.

In addition, the guidance seeks to provide an approach to differentiate the levels of regulatory oversight of particular changes on the basis of known impact and criticality of the potential change to product quality. The ability to differentiate change expectations on the basis of actual product understanding is a natural extension of the approaches taken in ICH Q8 and Q11, where for example product and process understanding can establish a “Design Space” for manufacturing and control within which changes are not seen as requiring regulatory oversight. In the draft of Q12, this concept is further developed by the concept of “Established Conditions” (ECs), with discussion of how investment in understanding can impact submission expectations (with Appendix I of the draft guideline providing an illustration of CTD sections that contain ECs and Annex I suggesting illustrative examples of ECs for both chemical products and biological products) and post-approval change management expectations. Importantly, the guidance discusses how this approach could be used for existing products, where the manufacturing process may have been described without any differentiation of change management expectations, leading to inefficient use of both industry and regulatory resources.

The draft guideline also includes a suggested system for the collation of such “agreed” regulatory change mechanisms for a product via use of a product lifecycle management (PLCM) approach, wherein the agreed changes can be clearly collated alongside the manufacturing commitments and the agreed (lesser) change reporting category for the changes. Annex III of the draft documentation provides an example of a PLCM document.

The guideline also contains content describing the pharmaceutical quality system (PQS) change management expectations (with Appendix II of the guideline providing further illustration of principles of change management) and the relationship between industry and regulators and importantly between regulatory assessment and inspection needed to support strong implementation of the approaches within Q12.

The draft guideline clearly already provides tools and approaches for change management of immense potential value. Nevertheless, the opportunity to comment on the draft is always an important step in the development of an ICH guideline, and it is important to ensure that comments assist in providing the clearest possible final guidance that will be readily and consistently implemented to mutual industry and regulator benefit. It is noteworthy that the current draft of the guideline includes wording suggesting that some concepts may not be implementable at the current time across every region. It will be of greatest benefit if the tools and approaches as described and agreed in the finalized guidance will be available for use on as wide a global basis as possible, in line with the ongoing vision of ICH for science-based, harmonized, and efficient regulation of pharmaceuticals.

3 Pharmaceutical Development Q8(R2), Current Step 4 version, dated August 2009.

4 Quality Risk Management Q9, Current Step 4 version, dated Nov 9, 2005.

5 Pharmaceutical Quality System Q10, Current Step 4 version, dated June 4, 2008.

6 Development and Manufacture of Drug Substances (Chemical Entities and Biotechnological/Biological Entities) Q11, Current Step 4 version, dated May 1 2012.

7 Final Concept Paper Q12: Technical and Regulatory Considerations for Pharmaceutical Product Lifecycle Management, dated July 28 2014, endorsed by the ICH Steering Committee on Sept 9, 2014.

8 Technical and Regulatory Considerations for Pharmaceutical Product Lifecycle Management Q12, draft version endorsed on Nov 16, 2017.

////////////////ICH Q12, Guideline, Technical and Regulatory Considerations, Pharmaceutical Product, Lifecycle Management

Sorry, the comment form is closed at this time.