ICH M7

Table 1

| subject | highlights | authors |

|---|---|---|

| Is Avoidance of Genotoxic Intermediates/Impurities Tenable for Complex, Multistep Syntheses? | A survey of over 300 synthetic publications in OPR&D over a 10 year period clearly demonstrated that the synthesis of synthetic APIs was untenable without the use reactive, potentially mutagenic reagents/intermediates. That the principle of avoidance was fundamentally flawed | Elder, D. P.; Teasdale, A.(6) |

| Strategies To Address Mutagenic Impurities Derived from Degradation in Drug Substances and Drug Products | The paper outlines a strategy for the systematic assessment of the risk posed by mutagenic degradants, describing how this relates to stress testing and long-term stability studies. Within this it seeks to define appropriate thresholds for identification directly related to the extent of degradation | Kleinman, M. H.; Teasdale, A.; Baertschi, S. W. et al.(7) |

| Assessing the Risk of Potential Genotoxic Degradation Products in a Small Molecule Kinase Inhibitor Drug Substance and Drug Product | The degradation profile resulting from stress testing of galunisertib is described, focusing on formation of two N-oxides, examining the site of oxidation and the relevance of the pathway under typical storage conditions. | Strege, M. A.; Osborne, L. M.; Hetrick, E. M. et al.(8) |

| Mutagenic Alkyl-Sulfonate Impurities in Sulfonic Acid Salts: Reviewing the Evidence and Challenging Regulatory Perceptions | Provides a comprehensive review of the existing evidence relating to sulfonate esters, examining the comprehensive mechanistic and kinetic studies and safety data. It also examines the current regulatory approaches and how this appears misaligned with the data. | Snodin, D.; Teasdale, A.(9) |

| Mutagenic Impurities: Precompetitive Collaborative and Data Sharing Initiatives | Examines the nature, impact, and successes of a series of cross industry initiatives covering areas such as structural evaluation (Q)SAR, data sharing–aromatic amines, boronic acids, purging and degradation. | Elder, D. P.; Williams, R.; Harvey et al.(10) |

| Do Carboxylic/Sulfonic Acid Halides Really Present a Mutagenic and Carcinogenic Risk As Impurities in Final Drug Products? | Examines evidence that indicates that in the case of both sulfonyl and acyl chlorides that Ames positive results relate to generation of a reactive species, halodimethyl sulphides (HDMSs) through reaction with DMSO and that this is the root cause of a positive response. Confirmatory negative data from other test solvents is also provided | Amberg, A.; Harvey, J.; Spirkl, H.-P. et al.(11) |

| Boronic Acids and Derivatives—Probing the Structure–Activity Relationships for Mutagenicity | The primary purpose is to raise awareness of the potentially mutagenic nature of boronic acids and stimulate further discussion/research in the areas. It provides mutagenicity data for some 40+ examples, examining the current status of in silico predictions and postulates a potential mechanism related to oxidation of boronic acids to yield oxygen radicals | Hansen, M. H.; Jolly, R. A.; Linder, R. J.(12) |

| A Kinetics-Based Approach for the Assignment of Reactivity Purge Factors | Details an experimental approach that utilizes kinetic analysis to facilitate assignment of reactivity purge values. | Betori, R. C.; Kallemeyn, J. M.; Welch, D. S.(13) |

| A Generic Industry Approach to Demonstrate Efficient Purification of Potential Mutagenic Impurities (PMIs) in the Synthesis of Drug Substances | Based on vortioxetine and its associated PMIs predicted purge values based on the system described by Teasdale et al.(15) are compared with experimental values. The results show good correlation concluding that theoretical purge values can be used to predict purging of PMIs. | Lapanja N, Zupanĉiĉ B, Toplak Ĉasar R et al(14) |

| Evaluation and Control of Mutagenic Impurities in a Development Compound: Purge Factor Estimates versus Measured Amounts | The purging of MIs associated with the synthesis of MK-8876 were assessed using the approach described by Teasdale et al.(15)These predicted values were compared to measured values and shown to be conservative in comparison to experimental data. | McLaughlin, M.; Dermenijan, R. K.; Jin, Y. et al.(16) |

Figure 2. Alignment between the reaction of benzyl bromide with triethylamine in isolation and as a low-level impurity in the TBS protection of benzyl alcohol.

Another area addressed in the special edition is that of sulfonate esters. This relates to the use of a sulfonic acid, used to form an API salt and the potential formation of sulfonate esters through reaction with alcoholic solvents. Snodin and Teasdale(9) have reviewed the available literature information concluding that the extensive evidence supports the view that such concerns are grossly exaggerated. In parallel to this publication there have been a series of correspondences involving the EMA quality working party, the following points were released following discussion at the CVMP committee.(18)

“The Committee endorsed the QWP response to the EDQM request for an opinion on new information on alkyl sulfonates. The QWP reviewed the article from Snodin et al. QWP acknowledges the scientific rationale in this article and that the formation of alkyl sulfonates is very low and very much depends on the reaction conditions. This makes the presence of these mutagenic impurities at toxicologically significant levels unlikely. However, as the presence and formation of these alkyl sulfonates cannot be totally excluded, QWP proposes the following approach: marketing authorization holders should justify via Risk Assessment that alkyl sulfonates are not expected to be present for their product, which may be sufficient.”

Of concern within this text is the comment that the presence and formation cannot be totally excluded; this is despite the evidence pointing clearly to fact that it can.

Similarly at the end of February EDQM issued a press release relating to the Mesilates Working party.(19) Included within this, as well as information relating to analytical methods, was the following revision of the production statement.

“In addition to the elaboration of these methods, the Ph. Eur. Commission had also decided to revise the Production section of monographs on those active substances to further assist users: “It is considered that [XXX esters] are genotoxic and are potential impurities in [name of the API]. The manufacturing process should be developed taking into consideration the principles of quality risk management, together with considerations of the quality of starting materials, process capability and validation. The general method [2.5.XX] is available to assist manufacturers.”

This also goes on to state that:

“Marketing Authorisation Applicants are not obliged to perform the testing when they can justify via risk assessment that alkyl sulfonates are not expected to be present in their product.”

-

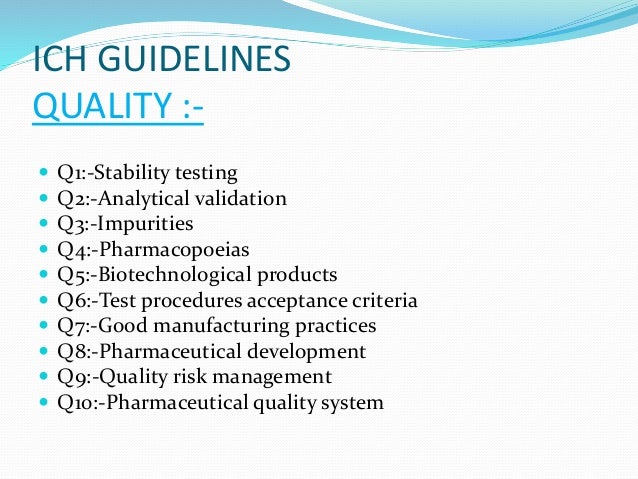

Q7 Good Manufacturing Practice

Code Document Title Previously coded Finalised Q&As: June 2015

References

-

1.ICH Q3D Guideline for Elemental Impurities.http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q3D/Q3D_Step_4.pdf(Dec 16, 2014).

-

3.Analysis of Oligonucleotides and their related substances; Okafo, G., Elder, D., and Webb, M., Eds.; Chapter 2, pp 22– 28; ChromSoc Separation Sciences Series ISBN 9781906799144.

-

5.ICH M7 Assessment and Control of DNA Reactive (Mutagenic) Impurities in Pharmaceuticals to Limit Potential Carcinogenic Risk.http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Multidisciplinary/M7/M7_Step_4.pdf (June 23, 2014).

-

6.Elder, D. E.; Teasdale, A. Org. Process Res. Dev. 2015, 19, 1437– 1446, DOI: 10.1021/op500346q

-

7.Kleinman, M. H.; Teasdale, A; Baertschi, S. W. Org. Process Res. Dev. 2015, 19, 1447– 1457, DOI: 10.1021/acs.oprd.5b00091

-

8.Strege, M. A.; Osborne, L. M.; Hetrick, E. M. Org. Process Res. Dev. 2015, 19, 1458– 1464, DOI: 10.1021/acs.oprd.5b00112

-

9.Snodin, D; Teasdale, A. Org. Process Res. Dev. 2015, 19, 1465– 1485, DOI: 10.1021/op500397h

-

10.Elder, D. P.; Williams, R; Harvey Org. Process Res. Dev. 2015, 19, 1486– 1494, DOI: 10.1021/acs.oprd.5b00128

-

11.Amberg, A.; Harvey, J.; Spirkl, H.-P. Org. Process Res. Dev. 2015, 19, 1495– 1506, DOI: 10.1021/acs.oprd.5b00106

-

12.Hansen, M. H.; Jolly, R. A.; Linder, R. J. Org. Process Res. Dev. 2015, 19, 1507– 1516, DOI: 10.1021/acs.oprd.5b00150

-

13.Betori, R. C.; Kallemeyn, J. M.; Welch, D. S. Org. Process Res. Dev. 2015, 19, 1517– 1523, DOI: 10.1021/acs.oprd.5b00257

-

14.Lapanja, N.; Zupanĉiĉ, B.; Toplak Ĉasar, R. Org. Process Res. Dev. 2015, 19, 1524– 1530, DOI: 10.1021/acs.oprd.5b00061

-

15.Teasdale, A.; Elder, D.; Chang, S.-J. Org. Process Res. Dev. 2013, 17, 221– 230, DOI: 10.1021/op300268u

-

16.McLaughlin, M.; Dermenjian, R. K.; Jin, Y. Org. Process Res. Dev. 2015, 19, 1531– 1535, DOI: 10.1021/acs.oprd.5b00263

-

17.Teasdale, A.; Fenner, S.; Ray, A Org. Process Res. Dev. 2010, 14, 943– 945, DOI: 10.1021/op100071n

-

20.Pharmaceutical CGMPS for the 21st Century—A Risk-Based Approach.http://www.fda.gov/downloads/Drugs/DevelopmentApprovalProcess/Manufacturing/QuestionsandAnswersonCurrentGoodManufacturingPracticescGMPforDrugs/UCM176374.pdf (Sept 2004).

-

21.Technical and Regulatory Considerations for Pharmaceutical Product Lifecycle Management.http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q12/Q12_Final_Concept_Paper_July_2014.pdf (July 28, 2014).

-

22.ICH Q9—Quality Risk Management.http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q9/Step4/Q9_Guideline.pdf (Nov 9, 2005).

-

23.ICH Q10—Pharmaceutical Quality System.http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q10/Step4/Q10_Guideline.pdf (June 4, 2008).

-

24.Established Conditions: Reportable CMC Changes for Approved Drug and Biologic Products,http://www.fda.gov/downloads/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/UCM448638.pdf?_sm_au_=iNH61FD2WjHZP02F (May 2015).

Sorry, the comment form is closed at this time.