Charlotte

Charlotte Owing to the competitive nature of the pharmaceutical industry, researchers involved in lead compound generation are under continued pressure to identify and develop promising programmes of research in order to secure intellectual property.

The potential of a compound for therapeutic development depends not only on structural complexity, but also on the identification of synthetic strategies that will enable the compound to be prepared on the desired scale.

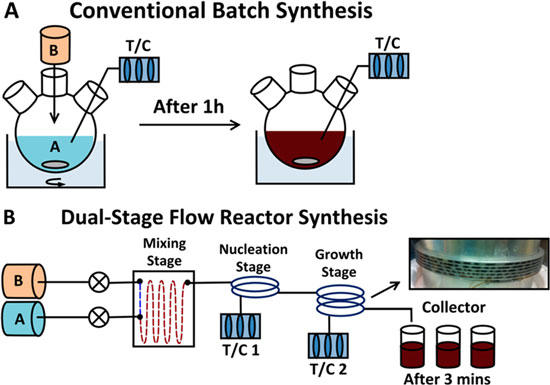

One approach that is of present interest to the pharmaceutical industry is the use of continuous flow reactors, with the flexible nature of the technology being particularly attractive as it bridges the changes in scale required between the initial identification of a target compound and its subsequent production.

Based on these factors, a significant programme of research is presently underway into the development of flow reactors as tools for the synthetic chemist, with the transfer of many classes of reaction successfully reported to date.

This article focuses on the application of continuous flow methodology to drug discovery and the subsequent production of pharmaceuticals.

Affiliation

Floris P.J.T. Rutjes

Floris P.J.T. Rutjes