Boldenone Undecylenate

cas 13103-34-9,

- Androsta-1,4-dien-3-one, 17β-hydroxy-, 10-undecenoate (7CI,8CI)

- (17β)-17-[(1-Oxo-10-undecenyl)oxy]androsta-1,4-dien-3-one

- 10-Undecenoic acid, ester with 17β-hydroxyandrosta-1,4-dien-3-one (8CI)

- Ba 29038

- Ba 9038

- Boldefarm

- Boldenone 10-undecenoate

- Boldenone undecylenate

- Equipoise

- Parenabol

- Vebonol

Boldenone undec-10-enoate; 17b-[(1-Oxo-10-undecenyl)oxy]-androsta-1,4-dien-3-one; 17b-Hydroxyandrosta-1,4-dien-3-one 10-undecenoate

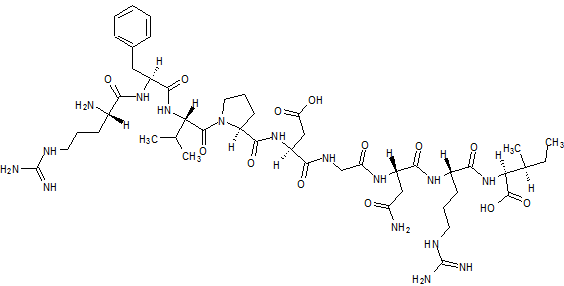

![CAS # 13103-34-9, Boldenone undecylenate, Boldenone undec-10-enoate, 17b-[(1-Oxo-10-undecenyl)oxy]-androsta-1,4-dien-3-one, 17b-Hydroxyandrosta-1,4-dien-3-one 10-undecenoate](http://www.chemblink.com/structures/13103-34-9.gif)

PATENT

http://www.google.com/patents/CN104327143A?cl=en

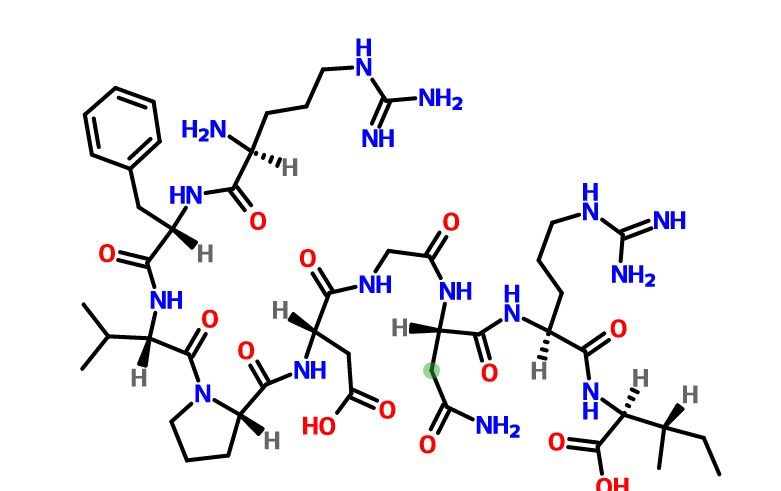

Boldenone (17β- hydroxy-1,4-dien-3-one male steroid, CAS: 846-48-0) The structural formula is:

Boldenone (Boldenone) is a derivative of testosterone, with a strong ability to support enhanced blood vessels, increase muscle, highlighting the blood vessels, increase appetite and other clinical role.

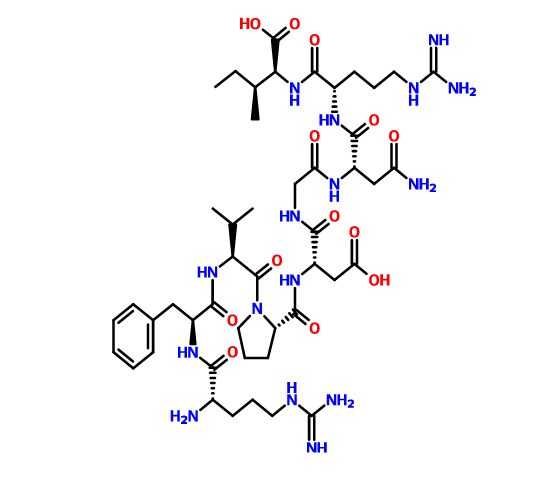

Domestic remain alcohol fermentation Preparation of 4- androstenedione (4AD) and 1,4-androstenedione (ADD), the company is numerous, very adequate supply of raw materials. Cheap and easily available 4AD and ADD steroid hormone drugs as key intermediates wide range of applications. Boldenone is an existing technology to the two aforementioned materials are prepared, in particular: (1) from 4-androstenedione as starting material Boldenone, synthetic route is as follows: C

After the above process route of the first reduction step of the reduction reaction of a 4- substrate androstenedione is added in one solvent dissolved in methanol, and then control the temperature dropping reducing a solution of potassium borohydride reduction reaction. According to this operation and the order of addition, the reduction reaction selectivity, impurities, must be introduced in the subsequent selective oxidation processes to ensure product quality; dehydrogenation process uses a chemical method dehydrogenation need to use more expensive as the dehydrogenation reagent DDQ using bio-dehydrogenation there is a long process cycle, easy contamination and other defects. There is a whole process line production process, long period, poor selectivity, multi-product, active manganese dioxide need freshly prepared, high production costs low.

(2) 1,4 androstenedione as a starting material Boldenone. Since ADD structure contains 3-one and two-keto-17-one, although I, 4- diene in the presence of the male left, increasing the structural stability of the three keto group, but still can not avoid the reduction reaction due 3 position ketone group is reduced to generate a 3-hydroxy-products. In order to avoid the reduction process due to 3-hydroxy-keto group is reduced to generate impurities, Chinese patent CN103030677A use of three-one ether of protection and then be prepared to restore technical solutions, synthetic route is as follows:

Said routing reduction step, a reduction reaction substrate ether solvent such as methanol was added at once dissolved and then put into a reducing agent, sodium borohydride, thanks in advance 3 ether ketone way of protection, in reducing Reaction to avoid the formation of by-products. Compared with the traditional 4-androstenedione route, eliminating the above process dehydrogenation reaction step, but there are still many steps, long period, higher production costs and other issues.

[0005] In recent years, adding different metal ions in the reduction reaction in order to improve the selectivity of the reduction reaction gradually attracted people’s attention. By participating in a metal borohydride multi carbonyl precursor compound remaining reduction reaction was added CeCl3 · 6H20, CoCl2 · 6H20, CdCl2 · (5/2) H20, CuCl, Cufc the like, to selectively reducing a compound of the structure in different positions keto, thereby obtaining reduced product having a different regioselectivity and stereoselectivity. In order to achieve the 1, 4_ androstenedione preparation Boldenone selective reduction objectives, technical personnel respectively potassium borohydride, sodium borohydride, boron and zinc borohydride as a reducing agent in the reduction reaction were added to the different After the metal ion, in accordance with a first reduction reaction substrate 1, 4_ androstenedione is added in one solvent dissolved, adding metal ions, the reducing agent added in the order reduction reaction. According to the above operation and the addition order, no matter how varying the process parameters have not been able to better achieve the selective reduction of 17-keto purposes.

[0006] Preparation Boldenone prior art process route, the reduction reactions using first reduction reaction substrate added in one solvent to dissolve, then add the reducing agent addition sequence and addition manner. Multi-keto-reduction reaction of the compound according to this method, there is a poor selectivity, multi-product of the state. In order to get qualified products often require the introduction of the first steps were selective oxidation or reduction reaction is not required to protect the keto group in the preparation process route, and then turn reduction, deprotection steps. Preparation prior Boldenone increased reaction step, extend the production cycle, improve the generation costs.

Synthetic route of the present invention are as follows:

References

Analytical Chemistry (Washington, DC, United States) (2011), 83(4), 1243-1251.

///////Boldenone Undecylenate